OMICRON partners shared promising results with stakeholders regarding its intelligent road asset management platform in an online meeting on 3 July 2024. Road managers, maintenance and construction specialists were among more than 50 members of the OMICRON External Advisory Board (EAB) who joined the 5th EAB workshop to hear progress and provide feedback. With half a year before the project ends, the focus in this event was on virtual reality (VR)-controlled robotic platform-based automated pavement crack sealing, Vehicle-to-Everything (V2X) communications for safer road inspections, and a Virtual Crisis Room to enhance emergency incident management.

OMICRON coordinator José Solís Hernández of CEMOSA provided a general update. The platform, comprising digital inspection, road digital twinning, decision support tools and smart construction and maintenance solutions, is nearing completion. Key technologies, including unmanned aerial vehicles (UAVs), a road digital twin, terrestrial inspection vehicles and a robotic modular platform, have undergone extensive in-lab and real-world testing. Further testing, at TRL (technology readiness level) 7 is scheduled in September. The final results, which will be presented online in the November EAB meeting and a final project conference in Madrid on 16 January 2025, will demonstrate the platform’s capabilities in improving road safety, reducing maintenance costs and increasing road network capacity, underscoring OMICRON’s commitment to transitioning from successful research and development (R&D) to market-ready solutions.

“We’re excited that OMICRON’s smart technologies are on track to achieve our ultimate aims — to help increase Europe’s road network capacity and to reduce maintenance costs, traffic disruptions, and accidents of road users and personnel.” José Solís Hernández, CEMOSA

- See the recording of José’s presentation about the OMICRON technology demonstration methodology.

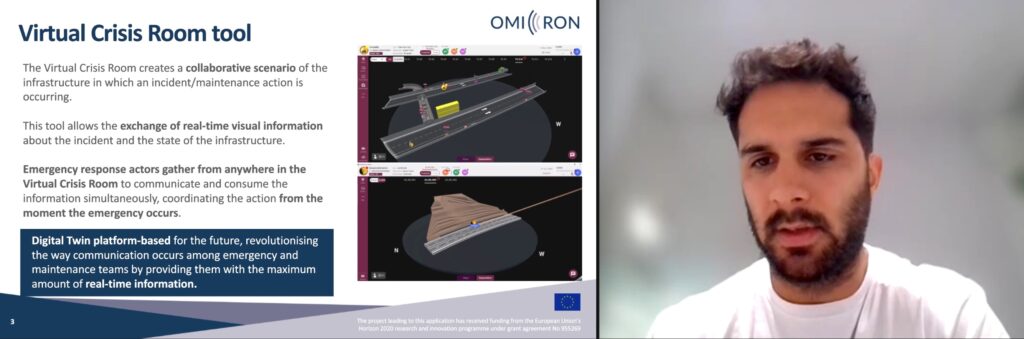

Virtual Crisis Room

Mixed-reality platform improves emergency and maintenance actions

Martín Rivas, project manager at OMICRON partner Indra‘s Innovation Transportation Department, introduced the Virtual Crisis Room. This digital tool improves emergency incident management by enhancing real-time communication and decision-making. It addresses issues like communication barriers and resource mismanagement by replicating traditional crisis rooms and using a digital twin to seamlessly share information among responders. Successfully piloted in Spain in Madrid’s M12 tunnel and on the A2 highway in Guadalajara, its effectiveness in managing incidents such as landslides and tunnel emergencies was demonstrated, with improved coordination, reduced damage and enhanced situational awareness. Future enhancements, to be made in close collaboration with road infrastructure management organisation Acciona, include integrating augmented reality glasses for detailed information in challenging environments.

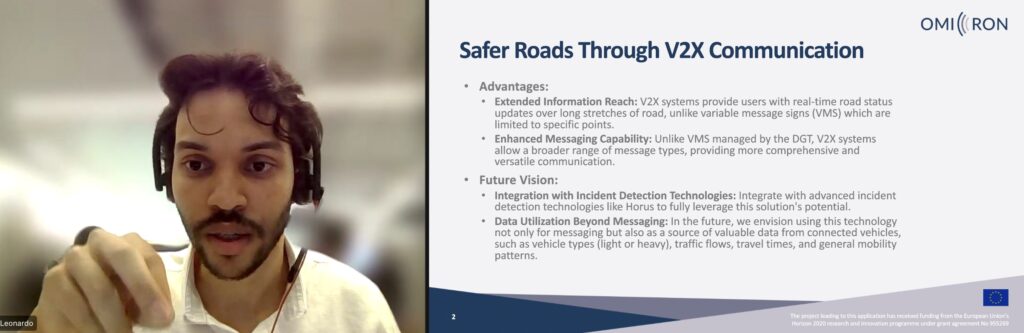

V2X communications

Roads that talk to vehicles enable safer, smoother transport

Martín Rivas also highlighted OMICRON’s testing of Vehicle-to-Everything (V2X) communications on the A2 highway near Guadalajara. The aim is to enhance road safety through real-time information exchange between vehicles, infrastructure and pedestrians such as road maintenance workers. V2X technology, using both mobile networks and short-range ITS-G5 antennas, significantly improved the detection distance of maintenance events by 600% and allowed drivers to receive warnings two minutes earlier than traditional methods. The testing demonstrated reductions in traffic disturbances, sudden braking and vehicle emissions. The demonstration also expanded real-time information sources by 15%, integrating data from Google Maps, Waze, DGT 3.0 and AccuWeather, showcasing V2X’s potential to revolutionise traffic management and improve road safety.

- See recordings of Martín’s presentation about V2X and his presentation about the Virtual Crisis Room.

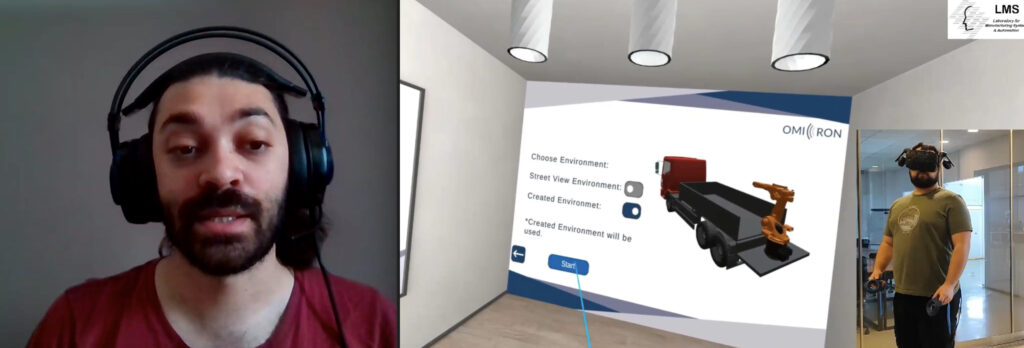

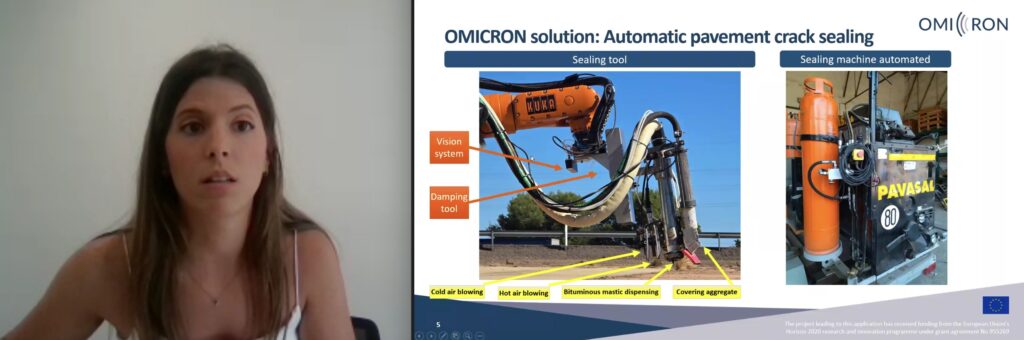

Robotic 3-in-1 tool with AR-VR control

Automated pavement crack sealing reduces costs and increases worker safety

Representatives of OMICRON partners Pavasal, Tekniker and LMS— the Laboratory for Manufacturing Systems & Automation at the University of Patras— presented results regarding the robotised sealing of pavement cracks, following demonstrations on the A7 highway in Valencia, Spain. The hardware includes a robotic platform with a sealing machine, aggregate deposit, air compressor, power generator and robot controllers. The software features modules for crack-detection, trajectory planning and efficient robot management. The use of augmented reality (AR) and virtual reality (VR) tools with live camera feedback allows workers to remotely control the robotic platform in real time from a safe distance.

Themis Anastasiou of LMS explained how the system synchronises virtual and real robot positions and enhances precision. Ander Ansuategi of Tekniker said that preliminary tests in controlled environments had validated the software’s ability to guide the robot trajectory, and outdoor tests confirmed effectiveness on asphalt.

“We designed algorithms to detect road cracks, plan and manage actions for robotic crack sealing. The remote operator moves the robotic arm and we optimise the movements to reduce time to execute the operation efficiently. We tested on real roads and successfully sealed cracks.” Ander Ansuategi, Tekniker

Sara Rabadan of Pavasal emphasised that, by integrating multiple operations into a single tool while ensuring precise planning and execution of actions with the vision-equipped robotic arm, the system:

- lowers maintenance costs by 13%,

- significantly increases worker safety, with a demonstrated 75% fewer workers needed in danger zones.

Laser-based pavement paint removal increases operator safety

The Pavasal–Tekniker–LMS trio also gave an update about the project’s second use-case for the OMICRON robotic platform: the automated removal of road lane markings using laser technology. Although the demonstrations achieved a 75% reduction in the personnel required in danger zones and 27% lower maintenance costs, the team concluded that more powerful lasers would be required to improve the speed of this solution and to make it commercially competitive.

- See recordings of the presentation about robotic sealing of road cracks and the presentation about robot-laser paint removal.

EAB: expert insights and feedback

During the 5th EAB workshop, guest presenter Leonardo Pires of leading infrastructure management organisation Acciona Concesiones discussed the advantages and future vision of the Virtual Crisis Room and V2X communications. Regarding the former, he highlighted that a centralised system with defined roles and access to updated information is crucial for crisis situations. The digital environment also supports training activities and the tracking of developments during a crisis for later analysis. Regarding V2X communications, he said that real-time status updates over long stretches of road and a continuous flow of more detailed information for drivers are important for improving safety and reducing accidents.

Other EAB members participating in the event provided feedback on the presented technologies and results through live online polling, a follow-up survey and by engaging in discussion. Key questions focused on: the time needed to digitally model a crisis situation in the Virtual Crisis Room and whether simulation data can be used for planning and training; the operational capabilities of the robotic crack-sealing prototype and potential impacts of different weather and lighting conditions; the productivity and cost-effectiveness of robotic solutions compared to manual methods; and the need for further trials and process quality improvements.

Next steps and opportunities

The last testing of OMICRON technologies will be carried out as part of the final demonstrator activities on the A1 between Florence and Bologna in Italy, in September 2024. This will include trials of the OMICRON digital inspection technologies, predictive maintenance technologies, and smart intervention and maintenance solutions.

Testing work on the OMICRON smart construction solutions has already been completed.

Final EAB workshop: online, 19 November 2024

Results from OMICRON technologies’ final demonstrations will be presented during the sixth and final External Advisory Board meeting, online on 19 November 2024.

Jesús Rodríguez Santiago, who chairs the OMICRON EAB, told the 5th workshop participants that the final EAB event will focus on demonstrator results regarding: road surveys with unmanned aerial vehicles (UAVs) — both long-range and multi-UAV inspections; terrestrial, vehicle-based road inspection; additional applications of the robotic modular platform such as installation and removal of cones, cleaning of road assets, and the installation of safety barriers; and the final results of the road digital twin and decision support tool. He will send background information and next meeting details to all invited EAB participants in mid-October—early-November.

To request an invitation, please contact OMICRON EAB chair, Jesús Rodríguez: jesus.rodriguez@upm.es.

EAB Membership

Membership in the OMICRON External Advisory Board and participation in the EAB workshops is by invitation only.

Participation provides:

- opportunities to hear inside insights and advance updates about the latest beneficial developments,

- influence activities by providing expert feedback from the perspective of relevant stakeholder sectors,

- access to all events’ meeting notes, slides and background documentation via the (members only) EAB documents part of the OMICRON website.

Final conference: Madrid, 16 January 2025

This collaborative event will highlight benefits, mutual areas of focus, extend discussions to include relevant issues and guest speakers, and will consider potential next steps for Europe’s roads.

Join us in Madrid from 09:00-18:00 CET on 16 January 2025!

See details